The family sewing machine was one of the first modern labour-saving domestic appliances. The must-have gadget of the mid-19th century the black ‘Japanned’ enamel machine, ornamented with gold scrolling and lettering, was proudly displayed in many drawing rooms. Treadles, hand cranked and later those driven with an electric motor all had a similar appearance and this style remained the standard until the introduction of machines with plastic housings and cases almost a century later. The plastic housings were much lighter in weight and many incorporated a carrying case or protective hood (1). The designs became much more utilitarian and something which packed up and could be stored away became the order of the day. Using plastics materials also meant that the machine housing could be of any colour and the employment of materials such as phenol formaldehyde, or bakelite as it was more commonly known, with its well-known resistance to electrical current, added an extra feeling of safety (2).

Historically, buttons were status symbols reserved for the elite and were treasures that could be transferred from garment to garment, but the availability of brightly coloured new plastics materials in the 20th century and developments in mass manufacturing techniques meant that the button became a cheap and cheerful fastening for all. Casein formaldehyde, a plastic derived from milk protein, was a popular material for button production. In appearance it could take many forms including mottled and pearl effect and imitation tortoiseshell. Casein readily accepts a surface dye and it could be polished mechanically or chemically to achieve a high surface shine (3). Buttons made from bakelite (4) were popular from about the 1920s through to the 1940s and subsequently nylon (5), and polyester buttons were introduced to the market (6).

The use of silk and cotton as sewing threads was complimented in the mid-1950s by the introduction of polyester thread. Less expensive than silk and more suited to use with man-made fabrics and high speed sewing machines, the synthetic threads have superior technical properties offering high tensile strength, resistance to abrasion and chemicals and are less likely to be affected by moisture, bacteria or insects. Spun polyester thread is now one of the most widely used sewing threads (7). Even the humble cotton reel was replaced by a plastic version. It is thought that the original wooden spools would have been returned for refilling or re-used as a plaything, but mass production and cheap materials means that they are now disposed of.

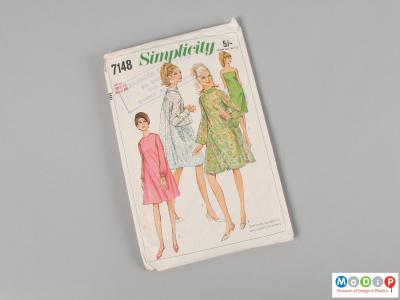

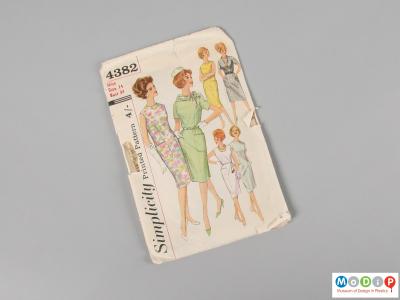

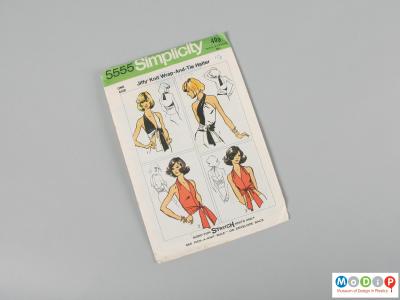

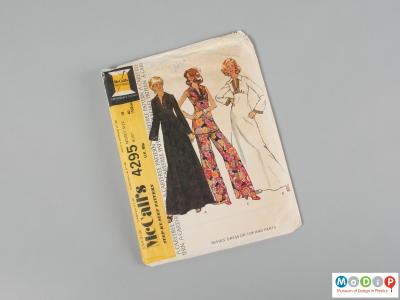

Home dressmaking and sewing has always been popular but has seen something of a revival in recent years. Sewing patterns (8 - 11) recommend the use of man-made or synthetic fabrics (12) and lightweight nylon zips (13 - 14) and sewing and mending accessories (15 - 19) have been found in sewing boxes for over half a century.