The notion of freezing food to preserve it is not a modern concept but it did not become commercially viable until the 1920s when American born Clarence Birdseye developed a method of quick freezing food for retail. As well as freezing and packaging by conventional methods, by the 1960s, together with Findus, Birds Eye had developed a method whereby food was presented for sale in a sealed sachet which could be taken from the freezer and immersed in boiling water to cook the contents. The plastic used to make some of these sachets or 'bags' was developed to allow the free flow of water whilst remaining sealed during immersion in the boiling liquid.

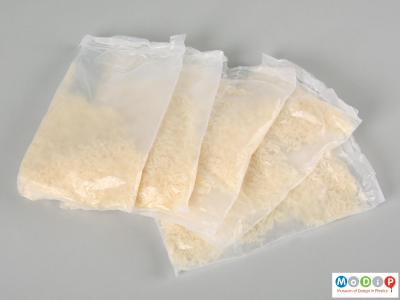

Other such bags hold food and sauces which are immersed into and exclude boiling water whilst the contents are cooked or heated. This method of boil-in-the-bag food preparation is also used for dried foods such as rice (1 - 3) and is a popular concept where minimum consumer effort is required to deliver freshly cooked, portion-size regulated food in minutes.

Colour changing or thermochromic additives in plastics have been in use since the mid 1980s. They are used both as a safety measure and as a 'temperature reached' indicator in a variety of products. The award winning Smart lid system™ (4 - 6) has been developed by Noshmell Pty Ltd., Australia. Designed to be used with existing foam and paper cups, the colour changing lid acts as an indicator to the consumer that the contents are hot and that the lid is fitted safely. When the liquid contents of the cup are cold, the lid remains brown. When it is fitted to a cup of hot liquid it rapidly changes to a red (for danger), reverting to brown as the contents cool. An ill fitting lid is indicated by inconsistencies in the colour. Such lids with small drinking spouts are an invaluable safety feature of modern 'on the go' beverage consumption. They help to eliminate the possibility of spillage and scalding.

An additional design feature of many cups is a band of raised ridged plastic (7), integral to the body of the cup which acts as an insulating barrier for the fingers.

The development of the non-drip, SimpliSqueeze® silicone valve by Seaquist Closures has turned the delivery of well known, everyday brands on its head.

Opening only under pressure, the valve allows the clean delivery of foodstuffs from the inverted package with immediate cut off once pressure is released. Hygienic and spill-proof, this closure has been employed most notably on the new squeezy Marmite jar (8), honey (9) and mustard jars (10).