We have recently received a very interesting donation of a Fisholow Plasticrate from one of our regular researchers, Roger Walker. This yellow crate was constructed for Fisher and Ludlow Ltd. out of polyethylene on The Projectile & Engineering Company Ltd. (Peco) 60 MR injection moulding machine.

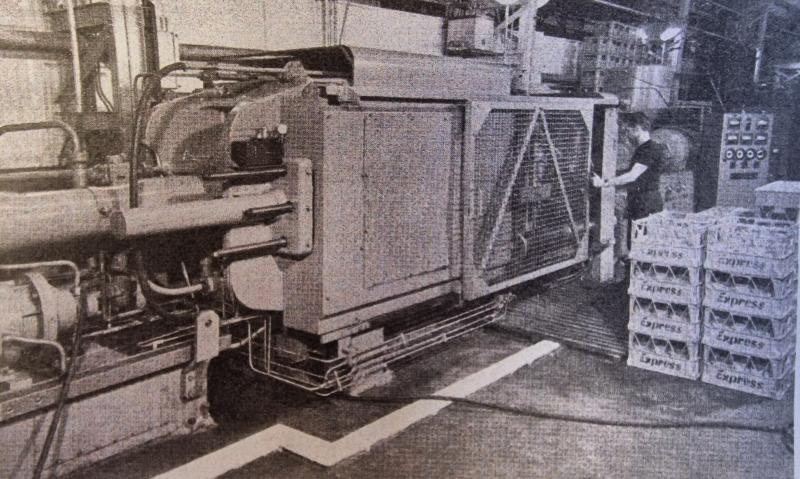

The Peco 60MR injection moulding machine used by Fisher and Ludlow to manufacture polyethylene crates

Picture Credit: Project Journal No.1: 1965

This particular crate was manufactured around 1965 as a trial prototype for Fisher and Ludlow to test the crate design with Peco 60MR machine and is stamped with the label “Fisholow Plasticrate” on both handles.

Internal view of the Fisholow Plasticrate (AIBDC : 009800) showing the 12 bottle compartments.

Side view of the Fisholow Plasticrate (AIBDC : 009800) where the stamped impression is visible on the handle.

Similar crates, manufactured for use by companies such as Express Dairy Co. Ltd and Ind Coope Ltd., held 12 or 20 1-pint milk or beer bottles and were either stencil-cut (Express Dairy) or hot-foil stamped (Ind Coope) along the side of the crate with the company name.

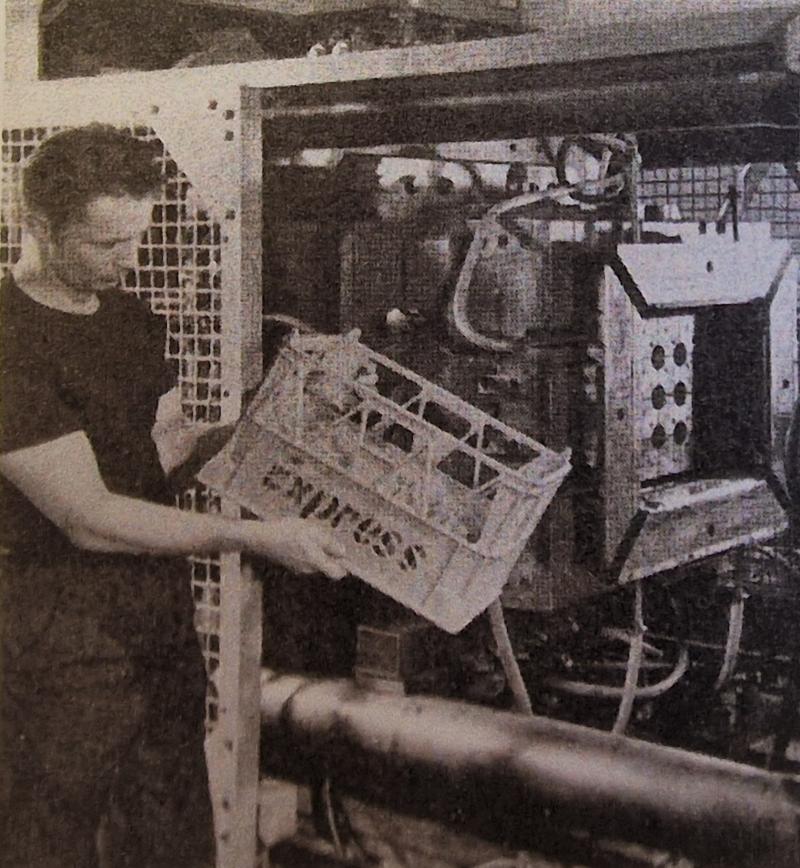

A Peco 60MR machine operator inspecting one of the 11,000 crates produced for Express Dairy. The "Express" logo has been stencil-cut into the side of the crate.

Picture Credit: Project Journal No.1: 1965

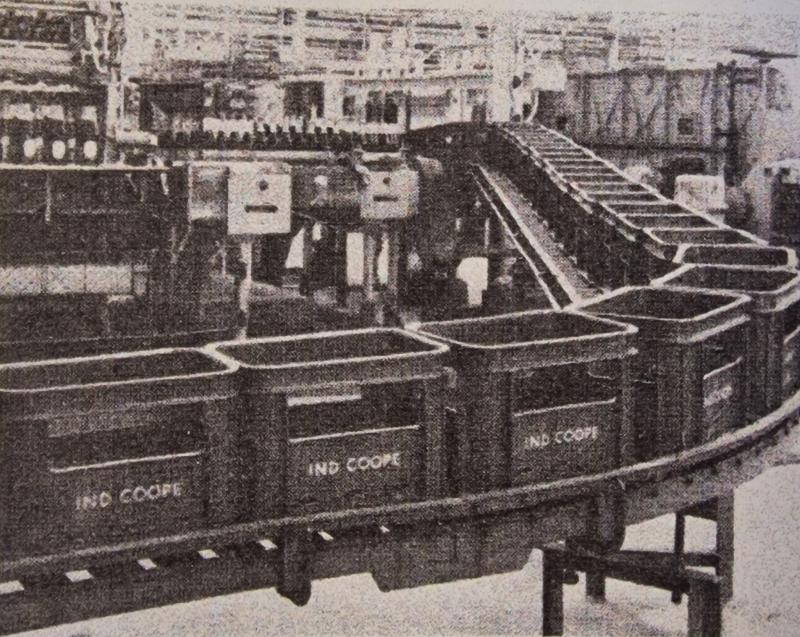

A portion of the 5,000 crates supplied to Ind Coope Ltd. The companies name has been hot-foil stamped onto the side of each crate.

Picture Credit: Project Journal No.1: 1965

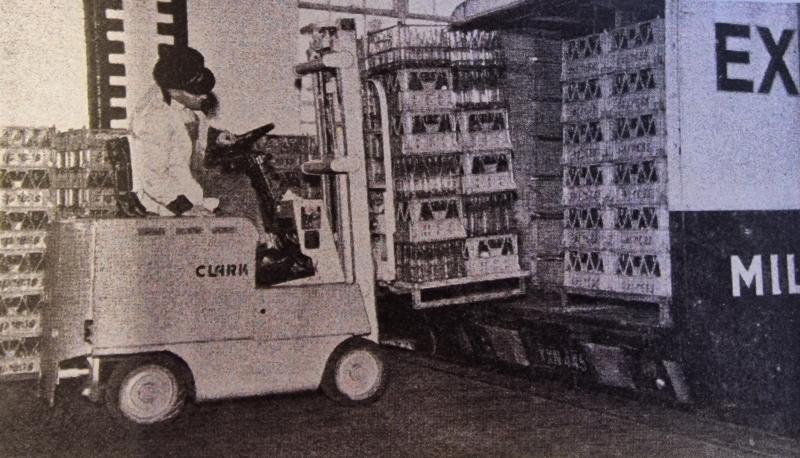

The significance of this prototype and subsequent plastic crates from Fisher and Ludlow is its unique design that allows it to be used alongside wire metal crates that were already in use on the filling and stacking equipment. The plastic crates were quieter, longer lasting, and much lighter to handle at 4 lb. compared to the 11 lb. wire crates. By creating a design in which both metal and plastic crates could be used together, bottling companies were able to gradually introduce plastic crates and replace the metal crates when necessary.

Plastic crates moulded by Fisher and Ludlow are loaded onto an Express Dairy delivery truck. Here you can see how the plastic and metal wire crates were used together.

Picture Credit : Project Journal No.1: 1965

One of my favourite aspects of this collection is how seemingly ordinary objects can have such a remarkable and dedicated history such as this Fisholow Plasticrate. If you have an interest in a particular object in the collection and would like to know more, we are happily taking suggestions for blog posts - you can reach us at modip@aub.ac.uk.

Shannon Carr, MoDiP Collections Officer

Sources:

- The Projectile & Engineering Company, Limited (1965). Polyethylene crates: Plastics crates catch on. Project the Journal of the Projectile and Engineering Co. Ltd. No.1. pp.6-9.

- https://www.hemmings.com/stories/article/fisher-ludlow